Published 10/2025

Created by DR AI

MP4 | Video: h264, 1280×720 | Audio: AAC, 44.1 KHz, 2 Ch

Level: All | Genre: eLearning | Language: English | Duration: 14 Lectures ( 2h 9m ) | Size: 1.25 GB

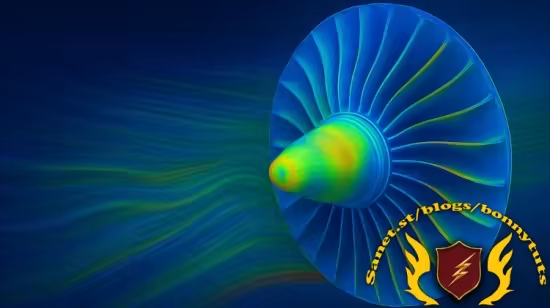

Learn to validate mesh quality, select solvers, and prevent simulation failures. Based on 10+ years of ANSYS expertise.

What you’ll learn

Predict mesh skewness failures before simulations using aspect ratio physics

Decode periodic error traps in turbines/compressors with boundary theory

Master wall function trade-offs: accuracy vs. stability in rotating machines

Spot turbulence model mismatches causing 30% efficiency drops in pumps

Reverse-engineer CFD garbage outputs using continuity/momentum forensics

Defend against vortex shedding chaos in blade rows with Strouhal theory

Solve transient rotor-stator errors with time-scale physics (no solver needed)

Detect false convergence from poor residuals/scaling in 3 steps

Validate simulations mentally using dimensionless numbers (Re, Ma, y+)

Build bulletproof meshes by controlling expansion ratios & cell quality

Requirements

Basic physics curiosity (e.g., “Why does fluid speed up in narrow gaps? etc”)

Patience to master CFD error-forensics

High-school physics (pressure/forces)

STEM background (engineers/students/hobbyists)

Description

This course makes use of artificial intelligence in 2 videos only to make complex theoretical concepts more intuitive. These are clearly marked in lecture 1 and 11 only, and are used to visually demonstrate abstract principles, complementing the core, expert-led curriculum.Why do industrial turbomachinery simulations often mislead engineers? Overlooking foundational theoretical principles – like 1mm mesh gaps causing 200% pressure errors (Module 1), y+ mismatch invalidating turbulence models (Module 2), or solver misapplication corrupting rotor dynamics (Module 3) – results in costly prototype failures. This course delivers applied theory to intercept simulation errors before hardware commitment. You will learn to:Diagnose mesh-induced errors (gaps, skewness) using continuity and momentum principles – exposing why a 1mm gap invalidates results (Module 1).Select turbomachinery-specific y+ ranges and wall functions to achieve ±5% validation against experimental data – avoiding common turbulence modeling pitfalls (Module 2).Contrast ANSYS Fluent vs. CFX solver architectures for rotating machinery applications – predicting stability issues in compressors or turbines through algorithmic differences (Module 3).Prevent vortex shedding failures with Strouhal theory and detect false convergence in residuals using a 3-step framework – securing transient simulations (Module 4).Based on 10+ years fixing $1M+ simulation disasters, you gain:The GIGO Prevention Protocol for mesh/turbulence integrityMental Validation Toolkit using Reynolds/Mach numbers and y+Solver Selection Decision TreeDesigned for:CFD Auditors reviewing third-party simulation reportsEngineering Managers mitigating prototype risksMechanical Engineers designing pumps, turbines, or compressorsZero software licenses needed. Master physics-first error detection to:Identify mesh flaws from CAD geometry aloneValidate resultsAnticipate solver limitations for turbomachineryEquip yourself with system-agnostic expertise – enroll to safeguard your turbomachinery projects from theoretical oversights.

Password/解压密码www.tbtos.com

转载请注明:0daytown » Auditing Turbomachinery CFD: Spot Costly Errors