EdgeCAM是由英国Planit Holdings集团(伦敦证交所上市公司)金属商务公司(原英国路径公司)开发的专业智能数控编程系统,主要应用在数控铣、数控车和数控线切割等数控加工编程领域。

EdgeCAM在全球模具加工、产品制造、机床生产等行业具有重要的影响力,在普通车削铣削编程、多轴铣切编程和车铣复合加工编程等方面具有鲜明的特色和优势。

EdgeCAM是一套功能强大、用途广泛、易学易用的智能数控编程系统,并为适应不同用户的需求采用了模块化设计方案。用户可根据自身的编程需求,选择不同功能的模块组合构成数控加工编程的CAM解决方案。EdgeCAM产品的研发和推广始终以满足全球加工制造业用户的需求为基础,以最快的速度向全球用户提供最新的数控编程功能,以满足不同用户的不同需要。在二十余年的产品开发和应用过程中,EdgeCAM已经在全球拥有了超过四万家正版授权用户。

完备的CAD数据接口 灵活的CNC代码输出

作为一个独立的CAM系统,EdgeCAM彻底解决了两个长期困扰数控编程人员的两个难题,一个是从CAD环境到CAM环境下的数据传递问题,一个是 CAM环境下生成的刀具路径与控制系统的匹配问题。另外,随着三维CAD软件的快速普及应用,EdgeCAM积极与CAD软件供应商进行广泛的合作,针对实体模型加工的模块包堪称行业的“标准”之作,具有极强的代表性。

EdgeCAM不仅一体化的提供了3D实体造型功能(EdgeCAM Part modeler 模块)和加工编程能力,更值得一提的是它对其他CAD系统的兼容性;当前主流的CAD系统(如Inventor?、 SolidWorks?、Solid Edge?、Pro/Engineer?、Pro/DESKTOP?、CATIA和Solid3000)的实体模型文件,可以不需要数据转换直接加载到 EdgeCAM的环境中,也就是说EdgeCAM可以直接读取诸如*.ipt、*.par、*.sldprt、*.catprt、*.asm、*.des 等模型文件,甚至是一些大的装配件,也可以直接加载到EdgeCAM中,彻底结束了从CAD环境下输出中间格式(*.IGES、*.VDA等)再读入到 CAM环境进行修改和编程的历史。当然,它也可以接受IGES、SAT、DWG、DXF、VDA、Parasolid?和ACIS等格式的模型文件。 EdgeCAM不仅可以直接读取这些CAD格式的模型文件,更可贵的是保留了实体模型所有的特征参数,加载到CAM环境后,实体模型的特征不但不丢失,而且可以进行自动的查找和分类。EdgeCAM对实体模型数据的这种无与伦比的兼容性得益于与众多CAD软件供应商之间的通力协作,是第一个与CAD软件供应商开展战略合作的CAM软件公司。最有说服力的是利用EdgeCAM针对实体模型文件进行编程并生成刀具路径之后,生成的刀具路径还可以与原有的CAD 环境实现动态关联,即一旦实体模型在CAD环境下被修改,在EdgeCAM中的刀具路径也可以根据修改后的模型自动更新。此功能更进一步的说明了 EdgeCAM真正地做到了对实体模型文件的无缝兼容。

EdgeCAM是在Windows环境下开发的应用程序,无论是界面的风格还是操作习惯都很容易被接受。这归功于EdgeCAM与微软合作并更换了原有的软件开发平台。三维图形化的刀具库和众多辅助工具都是基于Windwos 平台开发的,尤其是后处理编制系统,不仅不需要软件开发环境的支持,而且简单直观,容易操作,任何人都可以利用它来编制后处理模板;这个后处理编译模块已经作为EdgeCAM基本功能附加到每个产品模块中,即使最简单的产品包也包含了该模块;这个方式完全改变了CAM软件公司为用户定制后处理模板的惯例,而是为用户提供了这个简单易用的工具,用户可以使用它完成任何控制系统的模板配置工作。这不仅保证了EdgeCAM的实用性和完整性,而且给予用户良好的设备扩展性。另外,EdgeCAM提供的其他诸如NC代码编辑器股票、项目管理工具、机床通讯向导等功能也是基于Windows 系统下的插件,只要通过鼠标点击操作就可以轻易的完成相应的操作。

丰富的加工方法 高效的加工保证

随着三维CAD软件实体造型工具的普及,针对实体模型的编程正在越来越广泛的被应用。作为一个高效的CAM系统,EdgeCAM提供了众多智能的加工策略,从简单的轮廓铣加工到复杂的曲面加工;从车削外形到车铣复合加工;从投影加工到残料加工、清根加工、等粗糙度加工等数十种加工策略可供选择。无论是计算生成刀具路径速度还是刀具路径优化的手段,都体现出高效率的本质。

从简单加工到多轴编程 智能、便捷、随心所欲双色球

随着机械加工的发展,五轴联动加工设备和车铣复合加工设备的优势逐渐被人们所重视。在这一领域中,EdgeCAM更是进行了全心投入,开发出的高级车铣模块可以满足各类多轴车铣复合设备的复杂编程工作。此外EdgeCAM从10.5版本开始,向用户提供了支持5轴联动加工的数控编程模块,使EdgeCAM 的编程功能得到更大的扩展,更好地满足了用户的编程需要。

机床结构运动仿真 直观、逼真、明察秋毫

模拟加工对于CAM软件来说是必不可少的。EdgeCAM自主开发的仿真模块具有与专业仿真软件相媲美的功能,不仅可以显示夹具、毛坯、刀套等细节,还可以显示整个机床的运动。EdgeCAM在仿真加工过程中有多种显示方式,并可随时进行拖动、放大等动态操作。最值得一提的是可以将任意时刻的仿真结果以*.stl格式输出,输出的文件允许插入到EdgeCAM的加工环境下,被定义成下一工序的被加工对象或是毛坯,使得仿真加工不再是简单的检测和浏览工具;更增加了仿真功能的实用性。常规的过切干涉报警和指示等功能也有多种设置方式供用户进行选择。

Planit Edgecam 2013 R2 (x86/x64) | 3.52 Gb

Edgecam is market leading computer aided manufacturing (CAM) software for NC part programming. With unparalleled ease of use and sophisticated toolpath generation, it’s the only CAM system you’ll need for milling, turning and mill-turn machining.

Edgecam utilises your in house knowledge and experience to drive the CAM process with automation tools to suit different applications – allowing you to maintain your competitive edge.

Edgecam offers the following applications:

EDGECAM Production Milling

EDGECAM provides functionality to generate efficient toolpaths from wireframe and solid geometry on a variety of machine tool configurations, ranging from 2.5 axis to complex 3 to 5 axis milling machines.

EDGECAM Turning

EDGECAM Turning provides functionality for 2-Axis lathes, multi-turret configurations, sub-spindle turning centres and mill/turn machines. On a mill/turn machine, C-, Y- and B-Axis milling and drilling take place within the same environment, providing a fully integrated and associative programming solution.

EDGECAM 4 & 5 Axis

EDGECAM seamlessly integrates 4 and 5 axis simultaneous machining within its milling and mill/turn environment to allow a range of multiaxis cutting strategies to be applied to the most complex tooling or components.

EDGECAM Mill Turn

The uses of tail stocks, steadies, sub spindles, twin turrets along with C Axis, CY Axis and B Axis are regular features on today’s Multi-Task machine tools. In this collision rich environment, Edgecam’s turning and milling combinations provide a safe machining environment.

EDGECAM 3D Milling

EDGECAM features an extensive suite of advanced 3D cycles that is ideally suited for the rapid generation of optimum toolpaths for all surface and solids machining needs.

EDGECAM Part Modeler

EDGECAM Part Modeler is a cost effective, 3D modeling tool specifically designed for quick and simple construction and/ or modification of solid models prior to manufacture.

EDGECAM Strategy Manager

EDGECAM Strategy Manager encompasses the best from the principles of rules, knowledge and feature based machining and utilizes these to produce a fast, reliable and highly automated solution for solids machining.

EDGECAM Waveform

Waveform roughing is a high speed machining technique that maintains a constant tool cutting load by ensuring the tool engagement into the material is consistent. The tool path moves in a smooth path to avoid sharp changes in direction which maintains the machine tool’s velocity.

EDGECAM Solid Machinist

EDGECAM Solid Machinist is a powerful and seamlessly integrated CAM system for generating milling and turning machining strategies and NC code from solid models.

EDGECAM Wire EDM

EDGECAM’s Wire EDM is an efficient addition to its world class milling, turning, and turn/mill CAM software solution, providing greater productivity and increased flexibility through a single source solution provider.

EDGECAM Consultancy

The Edgecam Support Team is committed to providing the best possible support to our customers. It is our goal to maximise your Edgecam investment by dealing with your support requests in a timely and efficient manner and through ongoing improvements in our level of service.

EDGECAM MCS

MANUFACTURING CONTROL SOLUTIONS (MCS) is the total solution for all manufacturing data management and machine tool monitoring requirements.

Home Page – http://www.edgecam.com/

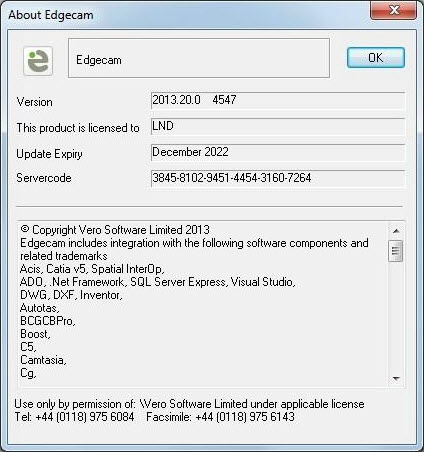

Planit Edgecam 2013 R4 x86/x64

Download rapidgator

http://rg.to/file/dd4e03aa8f65dafd0d420bb4636f076f/PLANIT_EDGECAM_V2013.R4-LND.part1.rar.html

http://rg.to/file/da31e45c73bf0626c25f7d762de908e4/PLANIT_EDGECAM_V2013.R4-LND.part2.rar.html

Download uploaded

http://uploaded.net/file/chjg4mzc/PLANIT_EDGECAM_V2013.R4-LND.part1.rar

http://uploaded.net/file/6ldcdizb/PLANIT_EDGECAM_V2013.R4-LND.part2.rar

Download Firedrive and 百度云

你是VIP 1个月(1 month)赞助会员,

转载请注明:0daytown » Planit Edgecam 2013 R2 x86/x64 数控编程

与本文相关的文章

- Compost 14.0.16.0 x64

- Siemens NX 2206 Build 9220 (NX 2206 Series)

- Siemens Simcenter Amesim 2404 x64

- InventorCAM 2023 SP3 for Autodesk Inventor 2018-2024 x64 Multilingual

- Siemens NX 2306 Build 8900 (NX 2306 Series)

- GibbsCAM 2024 v24.0.64.0 x64

- AVL Workspace 2024 R1 x64

- AVL Simulation Suite 2024 R1 x64

- Tekla Structures 2024 SP2 x64 Multilingual

- FunctionBay RecurDyn 2024 SP1 x64 Multilingual

- Compost 14.0.16.0 x64

- Altium Designer 24.5.1 x64