Mastercam 2026 引入了多项增强功能,旨在提高生产效率和加工精度。 这些新功能包括对复杂几何形状的优化加工,改进的刀具管理,以及更直观的用户界面。

以下是Mastercam 2026 的一些主要新功能:

加工增强功能:

高效加工复杂几何形状的平面区域:

优化了在复杂几何形状内加工平面区域的能力,在保证表面光洁度的前提下,缩短加工时间。

智能深度控制:

粗加工过程中,根据零件几何形状自动调整深度,优化加工策略。

增强实体孔功能:

使程序员能够更精确、更轻松地设计具有多种孔类型和配置的复杂孔特征,从而减少编程时间。

车削通用刀具目录支持:

在多台机器上快速创建刀具并实现标准化,简化了刀具管理。

安全区域运动优化:

提高了安全区域运动的效率和精度,减少了不必要的刀具移动。

放样曲面智能升级:

包括自动串连方向校正和引导曲线动态同步,方便曲面建模和加工。

自定义螺纹车削编程:

新增自定义螺纹车削编程功能,并支持Y轴刀具,提供更灵活的编程选项。

层别群组显示功能:

增强了刀路管理,方便用户组织和管理刀路,提高编程效率。

用户界面和工作流程改进:

全新平面管理器: 平面组织成树状结构,支持分组、嵌套、拖放、搜索和过滤,方便用户管理和组织平面。

增强的层级管理器: 提供更直观的层级管理界面,便于用户管理和组织模型中的不同元素。

三面板界面(几何选择、孔样式和高级选项): 简化了复杂孔特征的设计流程。

统一的工作流程: 用户能够从设计、分析、仿真到制造,实现无缝过渡。

其他改进:

铣刀刀架设计器: 可以更方便地设计和管理铣刀刀架。

车床通用刀具目录支持: 可以在多台机器上快速创建刀具并实现标准化。

总而言之,Mastercam 2026 旨在通过一系列增强功能和用户界面改进,提高加工效率、精度和生产力。

File size: 3.94 GB

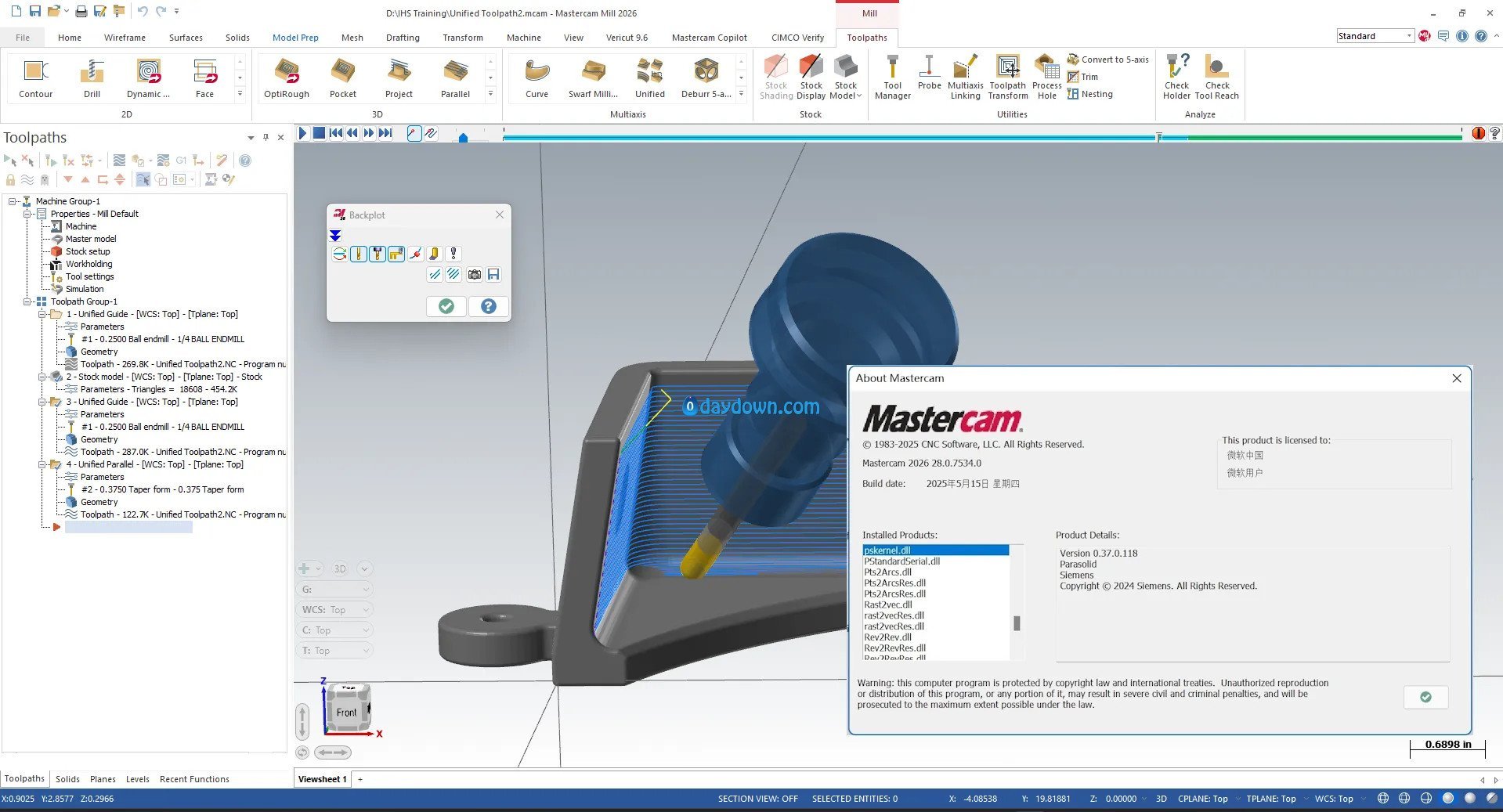

Mastercam 2026 delivers superior machining performance with advanced productivity tools and AI-enabled CAM intelligence for Mastercam CONNECT users.

What’s new in Mastercam 2026

Increased productivity through workflow efficiency

A key feature in Mastercam 2026 is its redesigned Solid Hole Functionality, which provides manufacturers with improved control over hole creation in solid models. The new three-panel interface—geometry selection, hole style, and advanced options—enables programmers to design complex hole features with precision and ease, reducing programming time for parts with multiple hole types and configurations.

Recognizing that tool management often creates programming bottlenecks, Mastercam 2026 introduces comprehensive improvements to tool handling and organization

The redesigned Mill Tool Holder Designer provides panel-based, intuitive visual feedback and streamlined tool assembly workflows, while Lathe Generic Tool Catalog Support enables rapid tool creation and standardization across multiple machines.

New Planes Manager: Features a powerful tree structure with drag-and-drop organization, group creation capabilities, and advanced search and filtering functions, enabling programmers to manage complex part setups more efficiently.

Enhanced Levels Manager: The new tree-structured interface provides improved customization options and workflow efficiency, allowing users to organize and manage part modeling, work holding, and toolpath creation entities with greater flexibility.

Safety Zone Motion Priority: Intelligent path optimization can now be accomplished through three new prioritization options which reduce air cutting time and improve overall machining efficiency.

Higher precision and control in complex machining

Mastercam 2026 includes several machining enhancements that enable complex machining with a high degree of precision and control, delivering advanced geometries and challenging part features with ease and confidence.

OptiRough Critical Depths: This new feature enables efficient machining of flat areas within complex geometries, reducing cycle times while maintaining surface finish quality. Manufacturers can now optimize roughing operations with intelligent depth control that adapts to part geometry.

Tapered Helix Entry: Addressing common challenges in deep pocket machining, this enhancement improves chip evacuation, provides better coolant and air access, and significantly extends tool life through optimized entry strategies.

Enhanced Loft Surface Creation: New blending algorithms and dynamic sync options enable smoother surface transitions and more predictable results when working with complex sculptured surfaces.

Expanded mill-turn and integration capabilities

Mastercam 2026 significantly expands mill-turn functionality with Classic Mill Toolpath Support, enabling manufacturers to leverage existing Surface Rough, Surface Finish, and Wireframe legacy toolpaths previously only found in Mill environments.

PrimeTurning updates now include enhanced angled cuts, pinch turning capabilities, and improved finishing options, providing manufacturers with more flexibility in complex turning operations.

AI-enabled CAM intelligence

For customers interested in exploring next-generation manufacturing technology, Mastercam 2026 includes access to an early adopter program featuring the Mastercam Copilot, an AI-powered programming assistant enabling the next wave of CAM intelligence.

The initial release of the Mastercam Copilot offers two primary functions: a Help system that provides natural-language guidance for programming questions, and a Command function that helps users by guiding them through the programming process through user interface automation. While still in Beta, early feedback indicates significant potential for reducing learning curves and accelerating programming workflows.

Mastercam is the most widely used CAM software worldwide and remains the program of choice among CNC programmers. It gives your shop the best possible foundation for fast and efficient milling. From general purpose methods such as optimized pocketing to highly specialized toolpaths like 5-axis turbine cutting, Mastercam ensures that you’re ready for any job.